Sustainable Packaging Trends 2026: What Brands in Europe Need to Know

Article

Actualizado:

21 ene 2026

< 2 min read

Compartir en:

Sustainable Packaging in 2026: The New Standard for Brands in Europe

By 2026, sustainable packaging is increasingly becoming a baseline expectation in Europe. Customers, regulators, investors, and procurement teams now expect packaging to be recyclable, low-carbon, and responsibly sourced by default.

What once differentiated a brand is steadily becoming expected, and an emerging commercial risk is the question many buyers and consumers now ask: “Why is this still plastic?” Packaging that appears outdated or unsustainable can weaken brand credibility, slow purchasing decisions, and even exclude suppliers from tenders.

Europe continues to lead this shift, driven by rising consumer awareness, regulation, and stricter procurement standards. Three regulatory frameworks are particularly influential:

Packaging and Packaging Waste Regulation (PPWR) – waste reduction, recyclability, and clearer labeling

Ecodesign for Sustainable Products Regulation (ESPR) – lifecycle thinking and product transparency

EU Deforestation Regulation (EUDR) – deforestation-free, traceable fiber sourcing

Together, these regulations are reshaping expectations and redefining what acceptable packaging looks like in the European market.

In this article, we explore the key trends shaping sustainable packaging in 2026.

1. Fiber-Based Packaging Becomes the Standard

Fiber-based packaging is rapidly becoming the standard for protective and secondary packaging. Corrugated board, molded fibre, paper-based cushioning, and honeycomb structures now cover most use cases previously dominated by plastics.

Fiber increasingly outperforms plastics where it matters most: it is recyclable at scale across Europe, aligns well with regulation, and benefits from strong regional supply chains.

Sustainability and cost are increasingly aligned. Continuous product development, economies of scale, and local sourcing have made fiber-based packaging highly competitive on price, while rising plastic and EPS taxes and Extended Producer Responsibility fees continue to increase the cost of fossil-based packaging.

Performance is improving as well. Advances in material engineering and structural design are expanding fiber-based packaging into heavier and more demanding applications, supported by continued progress in moisture and humidity resistance. In many cases, fiber is no longer an alternative — it is the preferred solution.

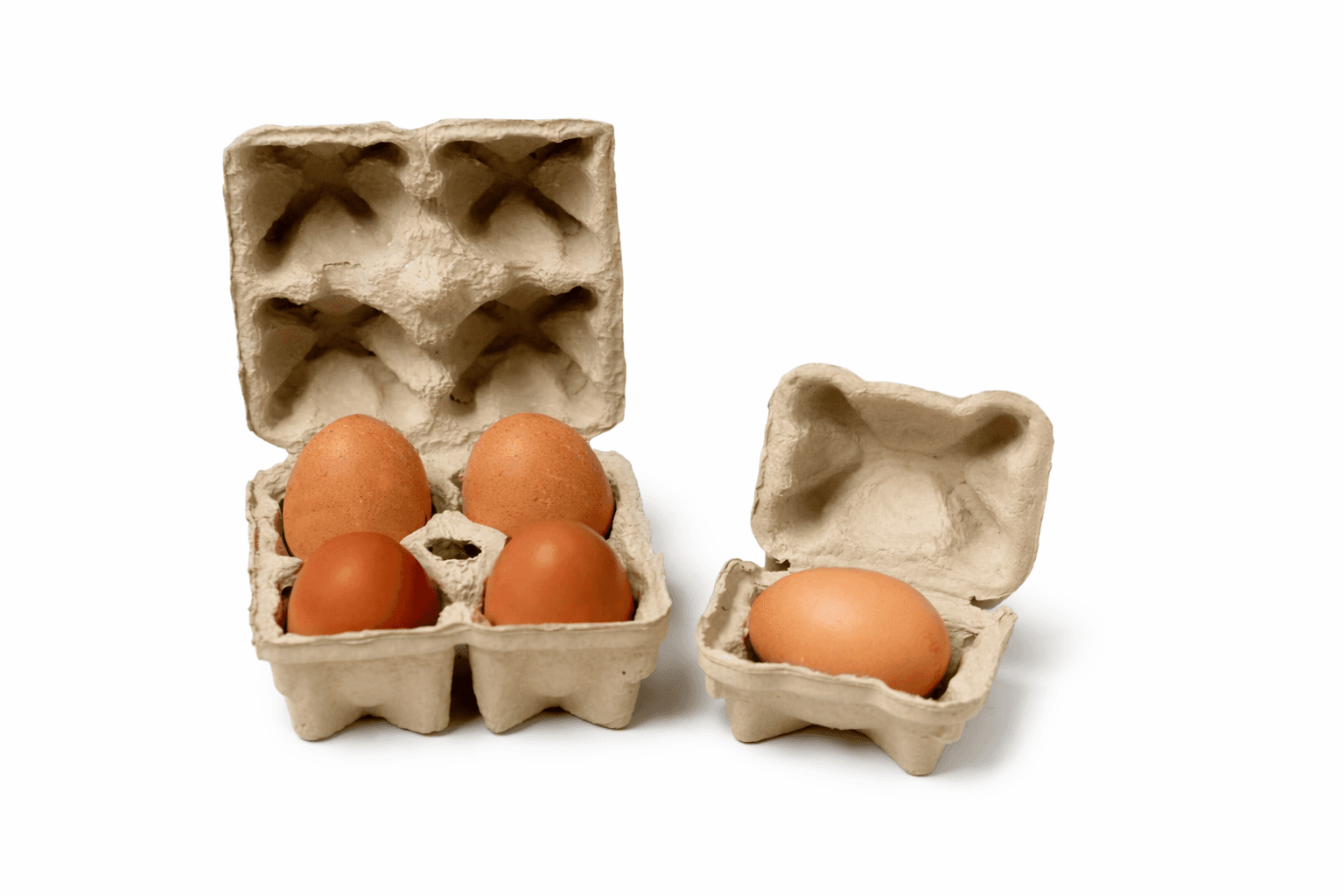

"Molded pulp is evolving rapidly, enabling a new level of precision and functionality in fiber-based packaging. Every day, we develop innovative designs, advanced tooling, and refined material formulations that focus on protecting products through complex geometries, tight tolerances, and smart systems. This progress allows molded pulp to move beyond simple cushioning into various applications that require more complex applications.

A clear example is our custom-designed egg packaging, engineered specifically to ship eggs safely through online meal delivery kits. The solution features an integrated snap-locking mechanism that securely closes the pack, protects each egg throughout distribution, and opens intuitively for the consumer. Innovations like this demonstrate how fiber-based packaging can now deliver sophisticated protection and mechanical performance once associated only with plastics or EPS—unlocking a growing range of high-value, paper-based alternatives.”— Natalie Davies, Managing Director, EGI

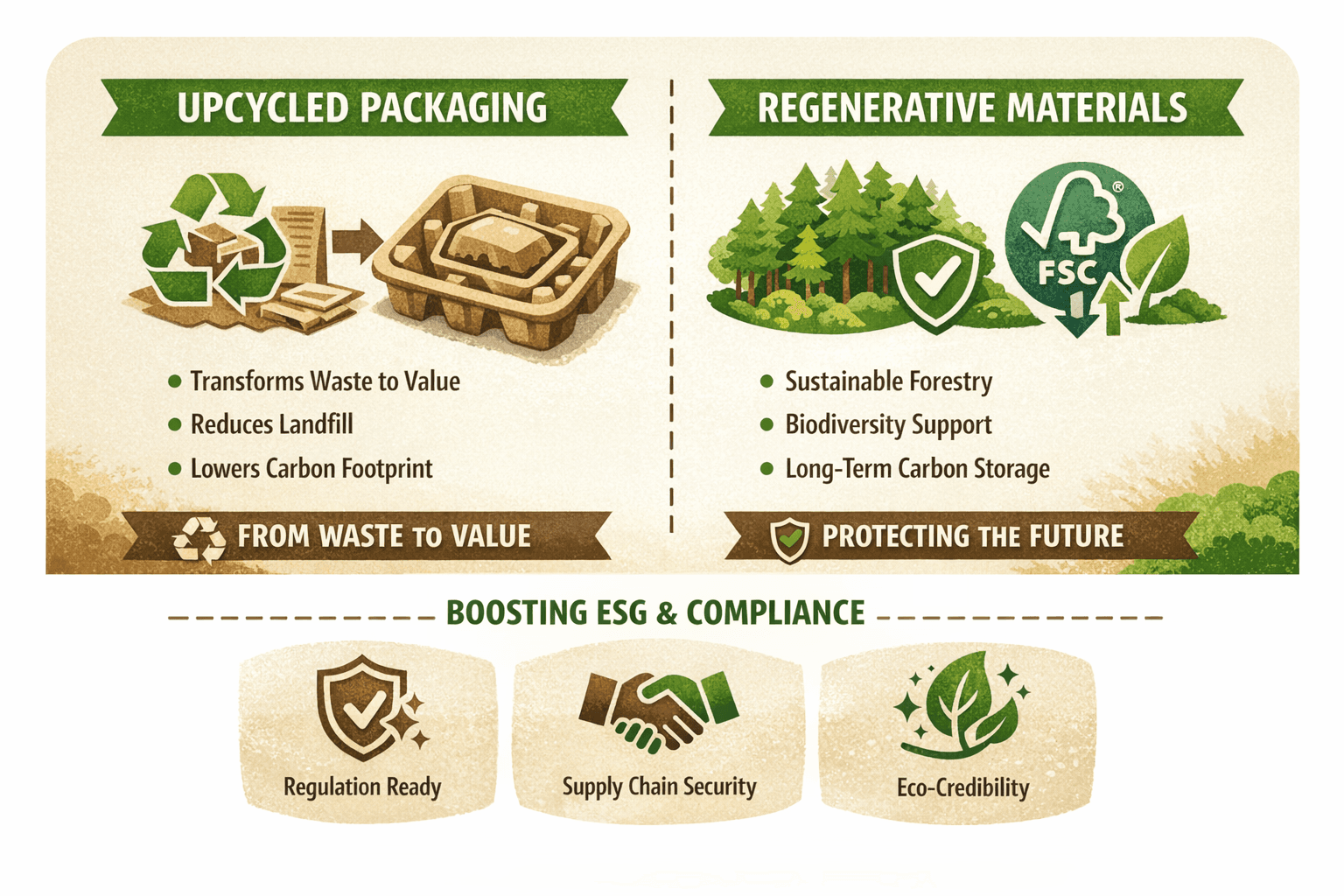

2. From Recycling to Regenerative and Upcycled Packaging Materials

The focus in sustainable packaging is shifting beyond recycling alone toward upcycled and regenerative materials.

Upcycled packaging transforms waste into higher-value applications, such as paper waste converted into high-performance molded pulp packaging. This reduces landfill, lowers the need for virgin materials, and typically delivers a lower carbon footprint while maintaining strong protective performance.

Regenerative materials go a step further by supporting positive environmental outcomes. Fiber sourced from responsibly managed forests, such as FSC-certified material, contributes to biodiversity and long-term carbon storage. The EU Deforestation Regulation (EUDR) is accelerating this shift by requiring traceable, deforestation-free fiber sourcing.

For brands, these approaches strengthen ESG credibility, reduce supply-chain risk, and support compliance with evolving European regulations.

3. Mono-Material Packaging and Real-World Recyclability in Europe

Mono-material packaging is designed using one primary material, making it easier to sort, collect, and recycle in practice.

Across Europe, the industry is moving away from mixed materials and complex laminates toward packaging that fits existing recycling infrastructure. This reflects a shift from packaging that is theoretically recyclable to packaging that is actually recycled at scale.

QR codes increasingly support this transition by providing clear, localised recycling instructions, helping consumers dispose of packaging correctly and improving recycling outcomes.

Practical example: To support mono-material packaging solutions, the Ryleon company Tampertech have developed paper-based tamper-evident labels and security tape. These innovations ensure the secure transport of valuable goods while enabling simplified and efficient recycling of used packaging.

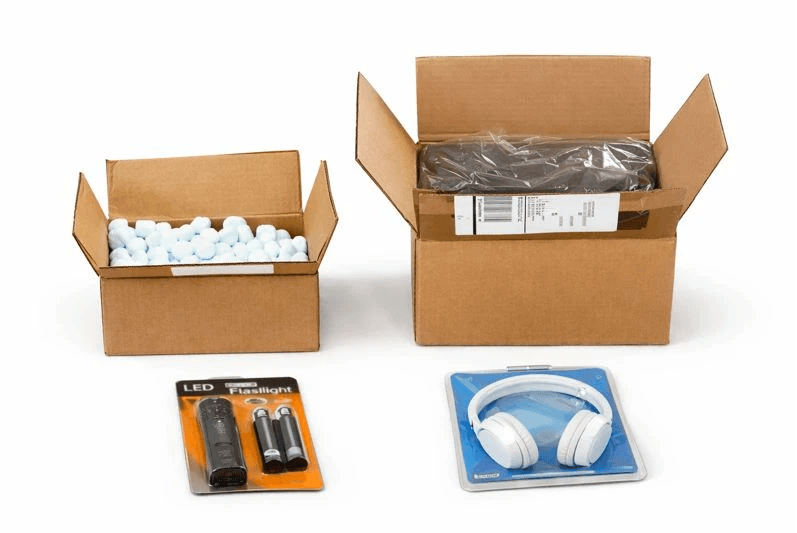

4. Material Minimisation, Lightweight Packaging, and Right-Sizing

Material minimisation focuses on achieving the required protection using less material overall.

Lightweight structures, right-sized boxes, and reduced void fill lower both material use and transport volume. This is where comparisons with EPS (expanded polystyrene) often arise.

While EPS remains very light as a material, molded fibre can compete at system level. Through smart design and geometry, fiber-based packaging reduces empty space, enabling smaller outer boxes and lower total shipped volume.

The result is lower material consumption, reduced transport emissions, and, in many cases, a lower total packaging cost.

5. Packaging as a Brand and Transparency Tool

Packaging is one of the most visible expressions of a brand’s sustainability efforts, with material choice and design offering immediate proof of credibility.

Brands increasingly use packaging to communicate clearly and transparently — through concise on-pack messages, clear end-of-life instructions, and QR codes that explain materials, sourcing, and environmental impact.

Transparency will become even more critical with the introduction of Digital Product Passports (DPPs). A product passport is a digital record that provides information on material composition, origin, environmental footprint, and recycling guidance. As DPPs are rolled out, expectations for accuracy, consistency, and openness will rise significantly.

6. Regulation as a Design Driver for Packaging in Europe

Regulation is no longer something packaging is adjusted to after launch — it increasingly shapes design decisions from the outset.

The Packaging and Packaging Waste Regulation (PPWR) drives recyclability and waste reduction, the Ecodesign for Sustainable Products Regulation (ESPR) introduces lifecycle transparency, and the EU Deforestation Regulation (EUDR) ensures responsible, traceable fiber sourcing. Companies that design packaging with these requirements in mind early benefit from lower compliance risk, faster approvals, and preferred supplier status with large buyers.

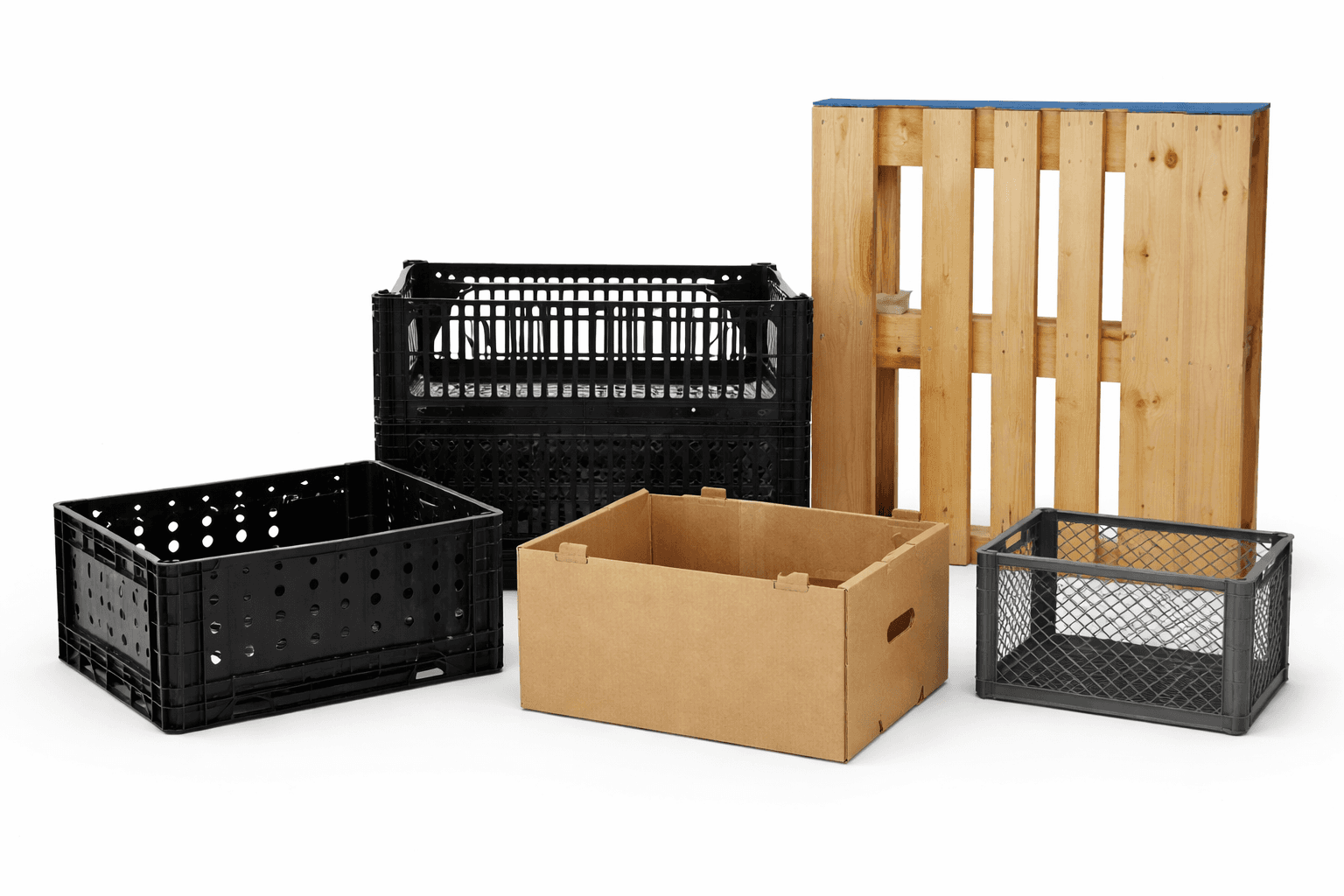

7. Circular Packaging and Reusable Packaging Systems

Circular packaging goes beyond single use by enabling reuse and refill systems that keep packaging in circulation for longer.

Reusable packaging is growing, particularly in controlled B2B environments. Packaging-as-a-service models, supported by QR codes, serialisation, and digital tracking, enable closed-loop systems where packaging is reused multiple times before recycling.

8. Consumer Expectations and “Packaging Shame” in 2026

Packaging shame describes the frustration or guilt people feel when packaging is excessive, difficult to recycle, or misaligned with sustainability claims.

Common triggers include over-engineered plastic packaging, mixed materials without clear guidance, and oversized boxes — often amplified through social media. In contrast, consumers increasingly expect fiber-based materials, clear recycling instructions, and minimal, purposeful use of material.

How Ryleon Helps You Stay Ahead in 2026

Sustainable packaging is rapidly becoming the preferred choice across Europe, as the industry shifts toward fiber-based materials, low-carbon design, and more transparent solutions. This transition is driven by rising customer expectations, stronger ESG ambitions, and evolving European regulations.

At Ryleon, we help customers translate sustainability ambitions into practical, high-performance packaging solutions. We develop fiber-based packaging tailored to specific products, applications, and supply chains. Through close collaboration and continuous product development, we support our customers in replacing plastics and EPS with solutions designed for performance, compliance, and circularity.

Contact us to speak with our packaging experts and explore how a tailored fiber-based solution can support your business in 2026 and beyond.

About Ryleon

Ryleon is a European group providing sustainable packaging and security solutions that protect physical goods and ensure safety and integrity throughout transport. The group specialises in fiber-based protective packaging and tamper-evident solutions, helping customers meet performance, regulatory, and sustainability requirements.

By combining fiber-based materials such as corrugated cardboard and molded fibre with security technologies, Ryleon supports a wide range of industries. The group grows through selective acquisitions of niche leaders and organic development, with a clear focus on innovation, reduced environmental impact, and long-term value creation.

Protecting what matters - Our customers product and the World we live in.